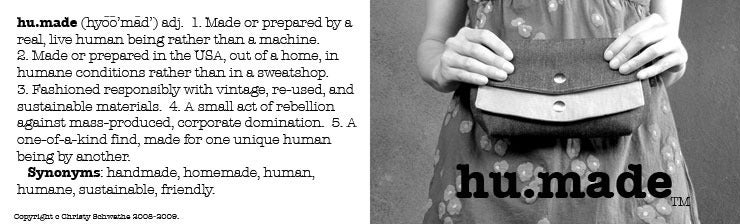

(image from hu-made, a one-woman "factory" in New Mexico. I am borrowing it because she so aptly describes what it is to have something handmade.)

I just have to come out and say it. Having something custom-made, handmade, made just for you, is not likely to be the most cost effective choice. In this day and age and world, you are almost certain to find a ready-to-wear, factory-made, mass-produced thing for much cheaper.

When garments are made in a factory, the patterns are often made by computer, with the punching in of "typical" measurements to get the proportions right. Designs are engineered to require the minimum amount of stitching and labor. Fabric is laid out layer upon layer upon layer and cut with what is essentially a large saw so that many copies can be cut in the time it takes to cut one. The garments are then assembled by teams of stitchers who are often paid minimum wage at best, each stitcher usually completing one single part of the garment over and over and over again, and passing it to the next stitcher for the next component to be completed. Factories have large amounts of space and can buy fabric and materials in bulk, wholesale prices. The prices are marked up at least 100% over the wholesale cost when you buy in the store (increase that percentage by a lot more when you are buying designer). And then, if you want an excellent fit, you have to pay for alterations on top of the price you paid in the store.

When garments are custom-made, the patterns are draped and drafted to suit your specific measurements and shape. Designs are engineered to your tastes and desires, and many couturiers will create a muslin mock-up of your design to try on you to ensure that the size and silhouette are exactly what you want. Fabric is laid out carefully and patterns meticulously placed to ensure that the grain and size are just right. Garments are then assembled by an individual who pays explicit attention to the details and can incorporate many hand-finishing techniques that are simply too costly to incorporate into mass-produced garments. Many people who create custom-made garments work from their home and often must buy their supplies and equipment in low quantities and at retail prices (even though we're usually pretty good at knowing where the deals are!) An artisan who works from home must incorporate many factors into the price of the goods made: the space used in the home in proportion to the rent or mortgage paid, the time in planning and conceptualizing the product, the cost of utilities and supplies and appliances (and their upkeep) that go into running a small business, the cost of gas and car maintenance for shopping trips, as well as the cost of materials and labor (I believe my time is worth more than minimum wage).

When you buy custom-made, you are paying for what you get. You are not paying for factories, shipping fleets, advertising, retail stores and pushy sales staff. It can be more cost effective for some people (especially if you are considering purchasing a designer label), but one should not seek custom-made simply because they are looking for a bargain.

If you believe that you are the kind of person who wants custom-made but just really can't fit it into the budget (and that is perfectly reasonable!), stay tuned to my next post for some tips on how to get a hand-made look for less.

No comments:

Post a Comment

What's on your mind? Have a topic you'd like me to look into? Need help with a project? Ideas or thoughts you'd like to share? I'd love to hear from you!